Bag Tipping Stations

Bag dumping, bag emptying, sack tipping

Follow us on TwitterQuestion, remark ? Contact us at admin@powderprocess.net

| Section summary | |||

|---|---|---|---|

| 1. Introduction | |||

| 2. Capacity | |||

| 3. Design | |||

| 4. Important design points | |||

| 5. Safety | |||

| 6. Common problems with bag tipping stations | |||

Bag tipping stations, also named bag dumping station, bag dumping platform or sacks tipping stations are often an indispensable process step for manufacturers to open and discharge bags of powder inside a process. Indeed, many ingredients are still delivered in 25 and 50 kg sacks all over the industry :

- Cements, mortars

- Grains, flours

- Chemicals

- Plastic pellets

1. What is a bag tipping station

How to empty bags of powder to hoppers and other process equipment ?

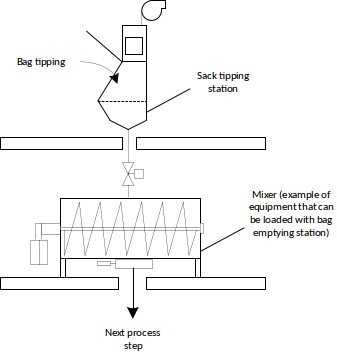

Bag unloading stations are used to open and empty bags efficiently, which means quickly and without dust emission, towards dry processing equipment. Tipping stations are especially useful to load hoppers, conveying lines or mixers. They are positioned right above the equipment they need to feed and product flowing from the opened bags is then falling by gravity to the next process equipment.

Although the function appears very simple, there are many different design parameters to take into consideration in order to have an efficient bag emptying station. This page is detailing the key design aspects to be addressed by manufacturers and plant operators.

2. Capacity

How many bags can be emptied per hour in a sack tipping station ?

The capacity (= number of sacks to be tipped / h) will be highly dependent on the workforce skills, strength and motivation, manipulating and opening sacks being a particularly demanding task. It will also be dependent on the surroundings of the platform, especially if the bags are provided directly to the operator on an ergonomic way. However, as a rule of thumb, one can consider that the capacity per station is around 2000 kg/h (which represents in between 1 to 2 bags tipped / min).

Some stations have 2 lids which allows to have 2 operators tipping at the same time and therefore increase the tipping throughput to around 4000 kg/h.

Semi automatic bag tipping stations have recently appeared on the market. Bags are dropped and opened automatically thanks to knifes on the tipping station, the operator having then only to shake and remove the empty bag. Fully automatic stations are also in development.

Top

5 Most Popular

1.

Pneumatic transport design guide

2. Ribbon

blenders

3. Powder mixing

4. Hoppers design guide

5. Measuring degree of

mixing

--------------

--------------

--------------

Top 5 New

1. Continuous Dry Mixing

2. Mixing speed

3. Mixer cycle time

optimization

4. Batch

/ continuous mixing comparison

5. Energy Savings

3. Design

The following items are to be taken into account when designing a sack tip station.

Hygiene / product risks

Sacks have to be opened while the station is opened to the environment, therefore the risks associated with the product must be evaluated and protective equipment provided to the operator when necessary (dust mask...). For very hazardous products, it is advisable to use glove boxes which are a specific type of dumping station where the operator can manipulate and open the sack without being in contact with the product, the station ensuring full containment.

Associated to this risk, the sack feeding station must be

equipped with an aspiration system that avoids to have dust

getting out of the station. The aspiration system is made of

bag Filters

and a fan. The fan must be sized according to the opening of the

station in order to provide sufficient suction power, which means

sufficient air velocity - speed - at the opening of the tipping

station. To be noted that it is not recommended to have deported filters (although

it could look economic for several stations) but rather have Filters

top mounted on the station so that dust can fall back directly on

the product, than collected elsewhere and maybe wasted.

Ergonomy

The station must be designed to ensure that the operator will have a position as comfortable as possible to empty bags. This is related to the station height which would be around 900 mm and the size of the support, or table, the operator can use to put the bag prior to opening which should be long and wide enough. It may be necessary to have the operator on a platform so that the tipping table is not too high, but this may be related to safety risks for the operator (stairs to get on the platform...).

Foreign Bodies

As the station is opened during the tipping, it presents an increased risk for the entry of foreign body in the process. The station should be equipped with the following equipment to prevent the entry of foreign bodies, from the environment or from the materials :

- Grid : prevents that large foreign bodies like bag / knife fall in the station, it will also help the operator support the sack during the tipping and avoid that the bag hits a process equipment located below (Vibrating Sieve for example)

- Sieve (can be vibrating)

- Magnets

Product properties

The flowability of the product to be discharged is a key parameter that will drive the design of the "bottom" part of the tipping station, i.e. the buffer hopper if it is required. It is indeed of crucial importance that the product flows easily outside of the dumping station, in order to make sure the capacity of the line is ensured, while ensuring that 100 percent of the material is discharged from the tipping station, to ensure 0 loss.

A powder rheology analysis of the powder(s) to be discharged must be done. If the product is very free flowing, no specific aid will be required. If issues the hopper of the dumping station must be designed accordingly, with steep walls and possibly vibrator or fluidizing pads. A knocker can be interesting to empty the station at the end of a shift for example.

Removing empty bags

Once emptied, sacks can be a source of dust. A bag collector must be positionned on the side of the station to avoid dust is spilled around the station or when removing the empty sacks. Some manufacturers can also propose a bag compactor to reduce the volume of the waste.

Manual or automatic bag dumping stations

Recently, manufacturers have developed new bag tipping stations that are either semi automatic, or automatic, with the primary goal of increasing the throughput of the bag dumping process.

| Station type |

Characteristics |

| Manual Bag Tipping Stations |

|

| Semi-Automatic Bag Tipping Stations |

|

| Fully Automatic Bag Tipping Stations |

|

4. Important design points

Figure 2 : Typical design of Bag Tipping Stations

When reviewing the design of a manual bag dump station, the following points deserve full attention :

Table 2 : Key design points of a Bag / Sacks Tipping Station

| Design point | Recommendation |

|---|---|

| Bag station access | The access to the Bag station should be done without having the need of a platform in order to prevent occupational safety risks. |

| Station height | The station must be around 900 mm from the floor in order to allow for a comfortable manipulation of the bag |

| Delivery of bags | Sacks should be delivered by a conveyor directly at tipping

height in order to reduce operator efforts and maximize

productivity. The bag supply must also be such that the

operator does not need to twist to grab the bags and tip them One alternative is to have a pallet lifter if bags are not delivered through a conveyor. |

| Dust aspiration | A filter, equipped with a suction fan, should be installed on top of the sacks feeding station in order to capture dust during tipping. |

| Foreign Bodies | Compact stations can integrate a Vibrating Sieve. All stations should include a grid. The cutting tool should be held by a chain in order to avoid to fall in the station. |

| Understand the impact of downstream process | Capacity and design will not be the same if the station is

equipped with a buffer hopper. Thanks to a buffer hopper,

tipping capacity can be higher as there is only 1 grid to go

through, but the buffer must be designed as to ensuring a good

flow out of the station. From the buffer hopper, the product

is typically fed to a product checking step (sieve, Magnets

) before being transferred to downstream processing |

5. Safety

As the station is open, risks related to rotating equipment that may be present below the station must be taken into consideration. Such equipment should be kept far away from the operator, or the grid in the station should in any circumstances prevent the operator to access.

Risk : ATEX

As every equipment processing powder, the ATEX risk needs to be considered when designing and sourcing a Bag dumping station. The 1st condition is to prevent dust emissions, which means that the Bag tipping platform must be equipped with an aspiration system. All equipment in the station and around the station must be rated according to the ATEX zoning assessment.

6. Common problems with bag tipping stations

Bag tipping stations are usually reliable equipment, however a certain number of issues may require some corrections :

Table 3 : common problems with bag dumping station

| Issue | Recommendation |

|---|---|

| Spillage of product during tipping | Review the size of the supporting table and the position of the grid to support the bag during slitting |

| Dust emission during tipping | Review the strength of the fan providing the dust suction. Make sure filters are clean Prefer top mounted filter and fan vs deported and centralized aspiration |

| Bad flow of product out of the tipping hopper | Check hopper slope, add discharging aids to promote the flow |

| Bad flow of product through sifter | Review vibration strength Adjust mesh size Adjust feed to sieve |

7. Bag tipping stations suppliers

There are numerous bag dumping station suppliers. However the user

must be careful when reviewing the design and check the criteria

above in order to select the best supplier.

Some sack tipping stations may also be available second hand on the

market. It can be a good option for manufacturers but an expert view

is required in order to assess if the 2nd hand proposal will fit the

need in terms of ergonomics, hygiene and possibility to implement in

the client process environment.

Source

Bag-Tipping Station design considerations, Thomas Lamotte, Processing Magazine, September 2018